SPC Eğitimi - İstatistiksel Proses Kontrol

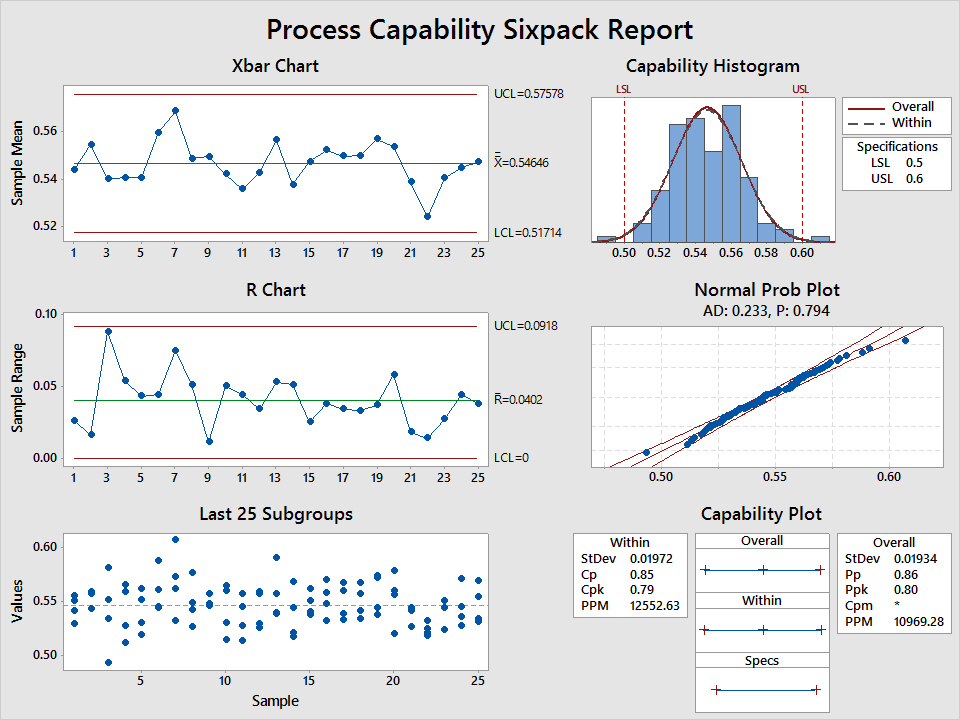

SPC Eğitimi, IATF ( Uluslararası otomotivciler birliği ) tarafından ürün içerisinde kritik spesifikasyonlarda prosesin sürekli olarak kontrol altında tutulmasını amaçlayan bir araçtır.Proses girdi ve çıktıları teorik olarak sabit kabul edilse de değişkenlik kaçınılmazdır. SPC Eğitimi ile oluşturulacak kontrol limitleri ile proses olabildiğince robust hale getirilerek müşteri güvence altına alınırken kalite maliyetleri düşürülür.

İstatistiksel Proses

Kontrol, süreçlerimizi kontrol altında tutarak hata oluşmadan önlemeye yarayan önemli bir araçtır. Otomobilimizde yakıtın bitmesine 50-60 km kala yanan ikaz ışığı hayat kurtaran bir kontrol limiti kullanım örneğidir. Bu sayede yolda kalmak yani problem yaşamaktan kurtuluruz. Süreçlerimiz için SPC tam da bu mantıkla çalışır. Bunun yanında süreç değişkenliklerini takip edip müdahale periyotlarını tespit edersek Kontrol Planlarımız, Bakım Planlarımız için doğru girdileri elde etmiş oluruz. Bu eğitimde amaç, SPC – İstatistik Proses Kontrol’ ü firmalarında uygulayacak çalışanların temel istatistik ve kullanılan araçlar konusunda yeterli bilgi seviyesinin kazandırılmasıdır.

SPC Eğitim içeriği

- Nicel Veriler

- Xort-R/S Kartı

- I-MR-R/S Kartları

- Nitel Veriler

- P Kartı

- NP Kartı

- C Kartı

- U Kartı

BU EĞİTİME KİMLER KATILMALI?

Kalite Kontrol ve Kalite Güvence Uzmanları

Ürün veya hizmet kalitesini izlemek ve kontrol etmek için SPC yöntemlerini kullanan bu profesyoneller, süreçlerdeki sapmaları ve problemleri erken aşamada tespit edebilir.

Üretim ve Proses Mühendisleri

Üretim süreçlerinde kaliteyi artırmak ve süreç verimliliğini sağlamak için SPC eğitimi alarak istatistiksel araçları kullanabilirler.

Üretim ve Operasyon Yöneticileri

Süreçlerin istatistiksel yöntemlerle kontrolünü sağlamak ve kaliteyi artırmak için SPC eğitimi alarak proses kontrolü hakkında daha fazla bilgi sahibi olabilirler.

Süreç İyileştirme Uzmanları

Yalın 6 Sigma veya diğer süreç iyileştirme metodolojilerini kullanan kişiler, süreçlerdeki değişkenlikleri ve sapmaları kontrol etmek için SPC eğitimini kullanır.

Üretim Teknisyenleri

Üretim süreçlerinde çalışan teknisyenler, süreçlerin izlenmesi ve kontrol edilmesi için SPC eğitimi alarak istatistiksel kontrol araçlarını öğrenebilirler.

Araştırma ve Geliştirme Uzmanları

Yeni ürün geliştirme veya süreç inovasyonu ile uğraşan araştırmacılar, süreç kontrolü ve kalite kontrolü için SPC eğitiminden yararlanabilirler.

Tedarik Zinciri ve Tedarikçi Kalite Uzmanları

Tedarikçilerden gelen ürün ve hizmetlerin kalitesini kontrol etmek için SPC yöntemlerini kullanarak tedarik zinciri kalitesini iyileştirebilirler.

Mühendislik ve Teknik Danışmanlar

İstatistiksel analiz ve proses kontrol danışmanlığı yapan profesyoneller, müşterilerine daha iyi hizmet sunmak için SPC eğitimi alarak istatistiksel süreç kontrol araçlarını kullanabilirler.

Genel Bilgiler

Eğitim Süresi

1 gün

Sertifikalandırma

Eğitim sonrasında yapılacak olan değerlendirme sınavında 100 üzerinden 80 ve üzeri puan olan katılımcılar “Gemba Akademi & Gemba Training Center Başarı Sertifikası” almaya hak kazanacaklardır. Yeterli puan alamayan adaylara ise “Katılım Sertifikası” verilecektir.